Our fine yellow and filter sands are mixtures of small rock grains and granular material, finer than gravel but coarser than silt, with particle sizes ranging from 0.06 mm to 1 mm. Morgan supplies high-quality sands in bulk and container shipments.

We offer a wide range of high-quality mining products, including limestone, processed and unprocessed calcium carbonate, kaolin, yellow sand, filter sand, and rock salt. Ideal for industrial, construction, and chemical applications, our products ensure reliability, consistency, and excellence in every project.

We provide high-quality mining products, including limestone, processed and unprocessed calcium carbonate, kaolin, yellow sand, filter sand, and rock salt. Our products are ideal for industrial, construction, and chemical applications, ensuring reliability and excellence in every project.

Our fine silica sand, sourced from Zaafarana, Egypt, is 95%+ pure SiO₂ with exceptional quality. Ideal for glass, ceramics, filtration, sandblasting, and precision industrial applications. Available in bulk with FOB, CFR, and CIF terms.

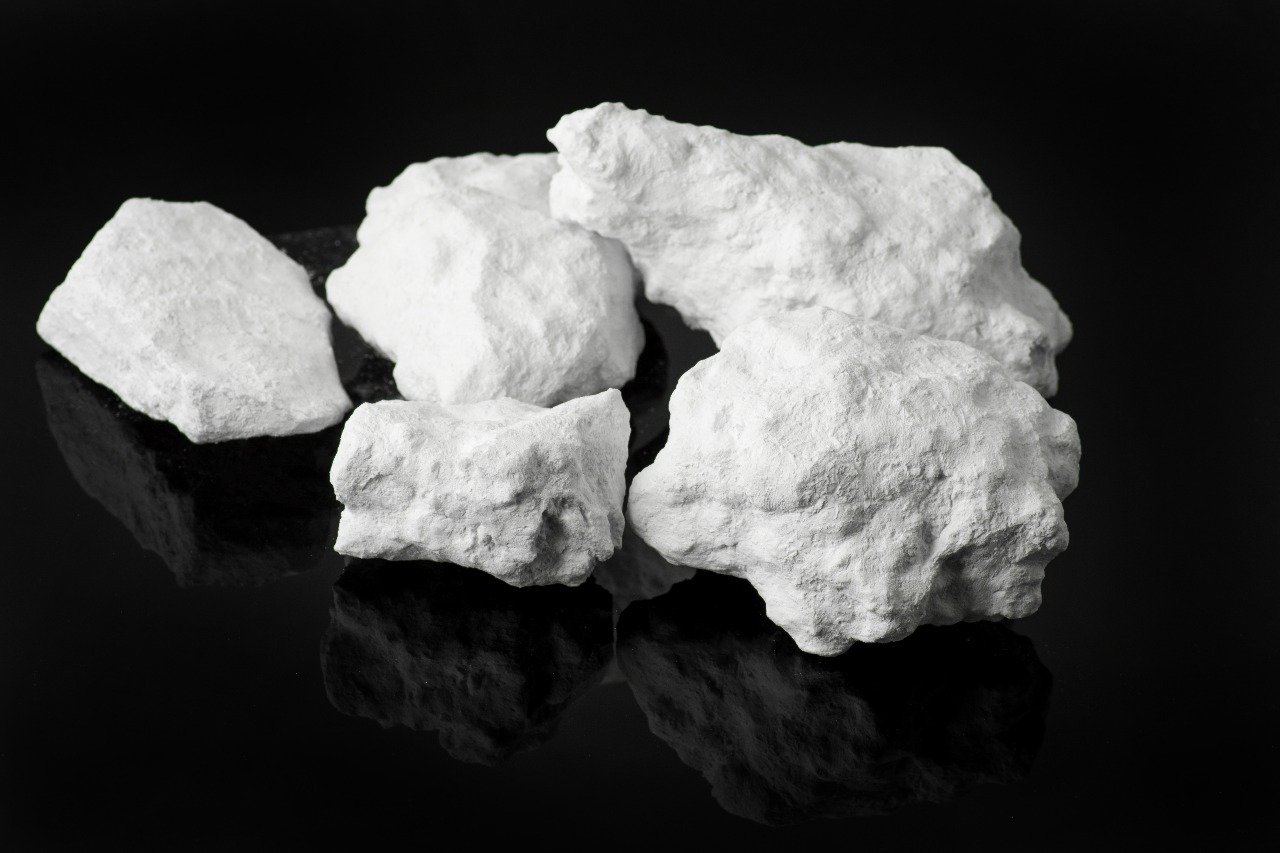

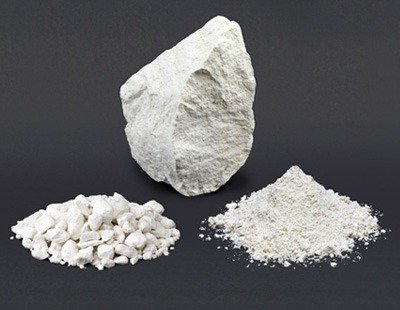

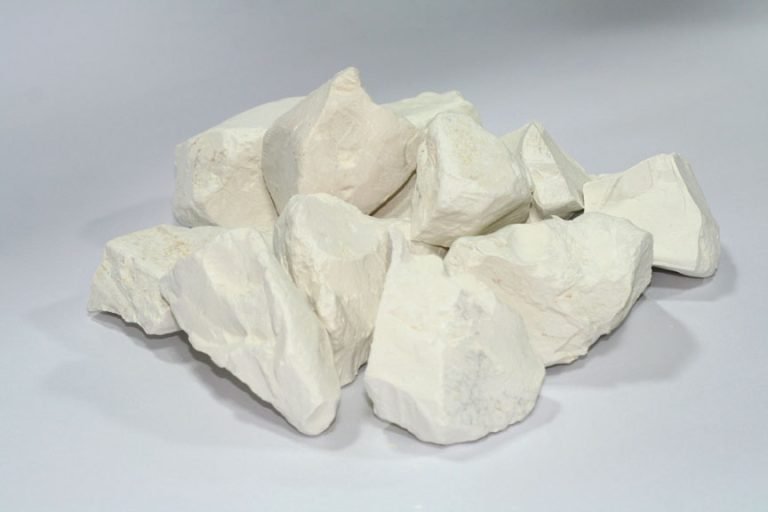

We provide premium limestone and processed or unprocessed calcium carbonate for diverse applications, including agriculture, construction, steel, glass, plastics, and animal feed. Our products ensure consistency, purity, and excellence for industrial and commercial projects.

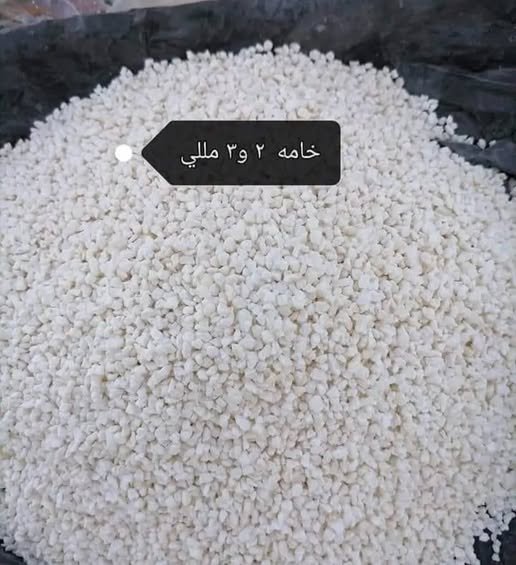

Our high-quality kaolin, rich in kaolinite, is ideal for ceramics, refractories, paper, rubber, and battery industries. Soft, white, and versatile, it’s also used in cosmetics and skincare for gentle cleansing and detoxifying effects.

Our fine yellow and filter sands are mixtures of small rock grains and granular material, finer than gravel but coarser than silt, with particle sizes ranging from 0.06 mm to 1 mm. Morgan supplies high-quality sands in bulk and container shipments.

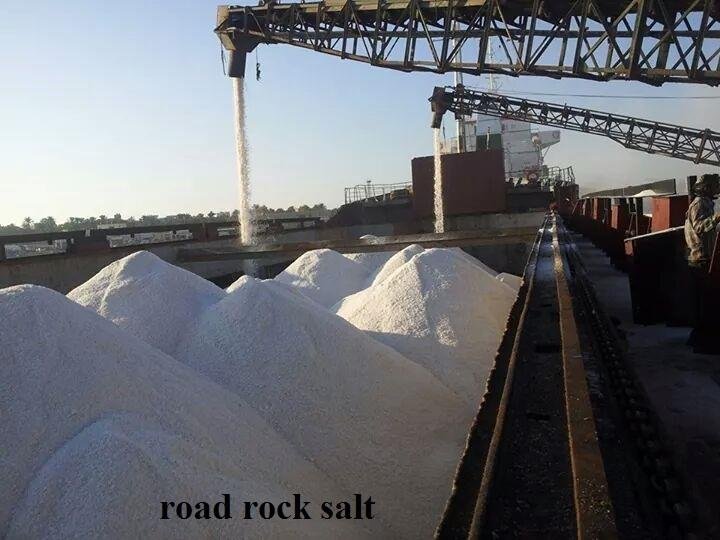

We offer a wide range of industrial and food-grade salts, including refined table salt, salts for textile, chemical, petroleum, fertilizer, caustic soda, soda ash, leather tanning, and water treatment. Our salts are also used in food production—such as sauces, snacks, beverages, dairy, canned foods, and frozen products—and for road de-icing and swimming pools.

Red iron oxide is a natural inorganic mineral derived from hematite, widely used as a stable and high-performance pigment. It provides rich red to reddish-brown colors and is highly resistant to light, heat, and chemicals, making it ideal for construction materials, paints, ceramics, plastics, rubber, cosmetics, and soaps. Suitable for both industrial and commercial applications.

Bentonite is a natural clay rich in montmorillonite, known for its high absorption and swelling properties. It is widely used in well drilling, agriculture, construction, personal care, and industrial applications. Available in sodium and calcium types, bentonite offers excellent performance in moisture control, soil improvement, and purification processes.

Red barite ore is a high-density mineral composed mainly of barium sulfate, with its red color resulting from iron oxide impurities. It is widely used in oil and gas drilling fluids, paints, plastics, ceramics, glass, and radiation-shielding materials. Known for its chemical inertness and heavy specific gravity, red barite is a reliable choice for industrial and commercial applications.

Quartz is a hard and durable natural mineral composed of silicon dioxide, widely used in industrial, technological, and decorative applications. Known for its high hardness, heat resistance, and scratch resistance, quartz is used in glass manufacturing, electronics, optics, jewelry, and engineered quartz surfaces for kitchens and bathrooms. Suitable for both industrial and architectural uses.

in the 0-600 micron size range consists of very fine particles, with most of them falling between 0.6 millimeters (600 microns) and 0.001 millimeters (1 micron) in diameter. This fine-grained silica sand is known for its versatility and numerous applications. Here’s a description of silica sand in the 0-600 micron size range: Particle Size Range: Silica sand in this size range is characterized by its small particle size, making it much finer than coarser sands commonly found on beaches. Purity: High-quality silica sand in this size range is typically composed of at least 95% silicon dioxide (SiO2), ensuring a high degree of purity. Color and Texture: Silica sand in this size range is usually light-colored, often white or light beige, and has a very fine, powdery texture. It feels smooth to the touch and can flow like a fluid when handled. Chemical Composition: The primary chemical component of silica sand is silicon dioxide (SiO2), making it chemically stable and resistant to most chemicals and environmental factors. Industrial Uses: Glass Manufacturing: This fine silica sand is a key raw material in glass production. It contributes to the clarity, transparency, and strength of glass products. Ceramics: Silica sand is used in ceramics and pottery manufacturing to provide structure and stability to clay bodies and glazes. Precision Casting: Fine silica sand is often used in precision casting processes, such as investment casting, where intricate details and high surface finish are required. Manufacturing Silicon Wafers: In the electronics industry, this fine silica sand can be used in the production of silicon wafers for semiconductor manufacturing. Paints and Coatings: It’s used as a filler in paints and coatings to enhance texture and durability. Filtration: Silica sand in this size range is commonly used as a filter medium in various applications, including: Water Filtration: Silica sand is employed in water treatment plants to remove impurities and particles from drinking water and industrial wastewater. Swimming Pool Filtration: Fine silica sand is used in pool filters to trap and remove debris and contaminants from pool water. Aquarium Filtration: It’s used in aquarium filters to provide effective mechanical filtration. Sandblasting: Fine silica sand can also be used in sandblasting applications for surface preparation and cleaning, especially when a smoother finish is desired. Mold Making: In some mold-making applications, particularly those requiring fine details and a smooth surface finish, this fine silica sand can be used as a mold material. Filler in Construction Materials: It’s used as a filler in various construction materials, such as grouts and cement-based products, to improve texture and workability. Agriculture: In agriculture, fine silica sand can be used in soil mixtures to improve soil structure, aeration, and drainage. The specific applications of silica sand in the 0-600 micron size range are vast and varied, depending on the industry and requirements. Its fine particle size makes it valuable for processes where precision, smoothness, and consistency are crucial. Egypt is a country rich in available mineral resources. Our silica sand quarry is located in the Zaafarana area on the Red Sea and contains some of the largest reserves of the highest quality sand in enormous quantities. We work on FOB, CFR, and CIF terms for containers and bulk.

Limestone is a common, chemical sedimentary rock formed primarily from calcium carbonate. It is generally light-colored and can also include fossils of calcium carbonate-containing organisms, like corals. Limestone can be found all over the world and is the major type of rock found in karst features (crystal cave systems found in bedrock. Limestone It is the raw material for the manufacture of quicklime (calcium oxide), slaked lime (calcium hydroxide), cement and mortar. Pulverized limestone is used as a soil conditioner to neutralize acidic soils (agricultural lime). Is overwhelmed to be used as aggregate—the strong base for many roads as well as in asphalt concrete. Geological formations of limestone are most of the great petroleum reservoirs; As a reagent in flue-gasoline desulfurization, it reacts with sulfur dioxide for air pollution manipulate. USES OF LIMESTONE Agriculture Industries Construction and Architecture Animal feed Other Uses Agriculture We have already said that limestone deposits contain mostly calcium carbonate compound. As such, this compound can be quarried to be used by the farming sector. Usually, limestone is crushed into smaller particles and various grades are produced. Finally, these products are sold as ‘agricultural lime or “Aglime” which is again used to neutralize soil acidity as well as free up soil minerals like phosphates. Industries There are several industries that make use of limestone. As such, powdered limestone is used in the textile, paint, paper, rubber, glass and plastic industries amongst others. They are mostly used as fillers. Apart from this, it is used in the steel industry for the production process where limestone is used to remove impurities. The minerals found in limestones are also used in pharmaceuticals, cosmetic products, baking soda, toothpaste, etc. Construction and Architecture Here limestone is quarried to service the needs of the building and construction industries. So the stone is cut into either slabs or blocks with specific dimensions. Some of its applications include sculptors, floor tiles, window sills, stair treads, and others. The famous pyramid of Giza in Egypt is made out of limestone. Additionally, limestones containing clay content are utilized in the production of cement. Limestone aggregate is also used in road and railroad construction. Other Uses of Limestone Crushed limestone is used as a filter stone in on-site sewage disposal systems. Limestone in powdered form is also used as a substance to absorb pollutants or control coal mine dust at many coal-mining facilities. Lime which is byproduct of limestone is used to neutralize acids and treat wastewater, industrial sludge, animal waste, and water supplies.

KAOLIN (CHINA CLAY) Kaolin is a mixture consisting principally of the mineral kaolinite and containing varying amounts of other minerals such as muscovite, quartz, feldspar, and anatase. Also known as china clay, kaolin is a soft white clay that is an essential ingredient in the manufacture of china and porcelain and is widely used in the making of paper, rubber, paint, drying agents, and many other products. It has a role as an excipient and an antidiarrhoeal drug. It contains a kaolinite. For cosmetics and skincare uses, kaolin clay has some important detoxifying and stimulating effects. The clay is a gentle cleanser for any skin type, extracting impurities and absorbing excess oils without causing inflammation or redness. Many people use it to purify their pores or treat acne and breakouts. Kaolin is white because is is a primary clay. That means it has not weathered and washed down somewhere picking up iron oxide in the environment. It is relatively high in alumina and thus refractory and fires to a very high temperature. Kaolin is one of the two important ingredients for porcelain clay bodies.

Red iron oxide (Fe₂O₃), also known as hematite, is a naturally occurring inorganic compound that appears as a red or reddish-brown powder. It is one of the most important sources of iron and is widely used as a safe and stable pigment in various industries, such as paints, ceramics, construction (cement and tiles), plastics, cosmetics, and even soap making, due to its ability to impart a rich red color that is resistant to light and chemicals.

Properties and Uses:

Chemical Compound: It has the formula Fe₂O₃ and is the primary component of rust. Chemically, it is known as ferric oxide or iron(III) oxide.

Natural Source: It occurs naturally as iron ore (hematite) and is one of the oldest pigments used throughout history.

Colors: Its colors range from reddish-brown to dark red, and it can appear in other colors, such as pale yellow (ochre), depending on the degree of hydration.

Stability: It is characterized by its high stability against light and most chemicals, and it is heat-resistant. Applications:

Construction: Coloring cement, tiles, mortar, and concrete.

Paints and Inks: A basic pigment for paints, coatings, and inks.

Plastics and Rubber: For color change.

Cosmetics and Soaps: For coloring lipstick, eyeshadow, blush, and soap (safe for skin).

Ceramics: As a coloring agent in ceramic manufacturing.

How it is obtained:

Extracted from natural hematite mines.

Produced industrially through the controlled oxidation of iron.

Bentonite is a type of natural clay composed primarily of the mineral montmorillonite and extracted from weathered volcanic ash. It is known for its high water absorption and swelling capacity, making it a versatile material used in agriculture, well drilling, construction, cosmetics (for detoxification and skin purification), and even as cat litter. The main types are sodium and calcium bentonite.

Composition and Properties:

Composition: Primarily composed of montmorillonite (calcium or sodium montmorillonite), it also contains elements such as calcium, magnesium, iron, and potassium.

Absorption: It absorbs large quantities of water (up to three times its weight) and expands significantly.

Plasticity: It is characterized by its plasticity and viscosity, transforming into a smooth paste when mixed with water.

Main Uses:

Well Drilling: Used to line oil and groundwater wells.

Agriculture: To improve soil quality, increase its moisture retention capacity, and reduce the need for irrigation.

Construction: As a moisture barrier in foundations and tanks. Personal Care: For detoxification, skin purification, and improving hair health.

Other Industries: Oil purification and cat litter (due to its clumping and odor-controlling properties).

Types:

Sodium Bentonite: Highly absorbent and expands rapidly, making it the most widely used industrially.

Calcium Bentonite: Used in various applications and known for its ability to absorb harmful substances.

Red barite ore is essentially barite (barium sulfate – BaSO4) that acquires its red color due to iron oxide (rust) impurities, unlike pure barite, which is white or colorless. It is primarily used as a filler in paints, insulation materials, and drilling materials in the oil industry. Its high density and chemical inertness make it industrially valuable.

What is barite ore?

Chemical composition: Barium sulfate (BaSO4).

Source: Found in hydrothermal fissures and sometimes with iron ores. Mines exist in Australia, Morocco, India, and other countries.

Properties: It is characterized by high specific gravity (heavy), insoluble in water, and chemically inert, making it an excellent material for various applications.

Why does it turn red?

The red color comes from the presence of impurities such as iron oxide (rust) within the barite crystal structure, along with silica and alumina, which change its original white color to shades of gray, brown, or red. Uses of Red (and Non-Red) Barite

Oil and Gas Drilling Fluids: The largest use (approximately 70-80% of production) is as a flocculant to increase fluid density.

Fillers: In the manufacture of plastics, paints, textiles, and automotive friction materials.

Glass and Ceramics Industry: To increase density and in the manufacture of LED displays.

Medical Applications: As a barium meal for radiography (although it is usually white for medical preparations).

Radiation Protection: In the manufacture of protective cements.

Quartz is a very common and hard mineral composed of silicon dioxide (SiO2). It is the second most abundant mineral in the Earth’s crust after feldspar. It comes in a variety of colors and forms (such as amethyst, citrine, and rose quartz) and is used in watchmaking, electronics, jewelry, and industrial surfaces (quartz marble) due to its durability and resistance to scratches and heat. It is also important in optics and modern technologies.

Its main properties:

Chemical composition: Silicon dioxide (SiO2).

Hardness: It has a hardness of 7 on the Mohs scale, making it difficult to scratch.

Transparency: It ranges from completely transparent (rock crystal) to partially transparent or opaque, depending on impurities.

Crystals: It usually forms hexagonal crystals.

Types and uses:

Natural quartz: Types such as amethyst (purple), citrine (yellow), rose quartz, smoky quartz, and tiger’s eye are used in jewelry and ornaments. Artificial quartz marble: A mixture of ground natural quartz, resins, and pigments, it is widely used for kitchen and bathroom countertops due to its stain resistance and ease of cleaning.

Industrial applications: It is used in the manufacture of glass, electronics (digital watches), optical instruments (it transmits ultraviolet light), and in building materials due to its strength.

Quartz in decoration:

It is available in modern colors (white, black, gray, beige) and various surface finishes, and is manufactured in polished or matte finishes to suit different modern and classic designs.